TL;DR: If you are a logistics or delivery company, we want to help you in monitoring & bridging the gaps and bottlenecks in your supply chain. We will make our location analytics product available to you free of cost for the next couple of months. Do get in touch with me on LinkedIn if you are interested!

Everything that’s been happening with COVID-19 has hit us hard and has forced us to think — how can we help in the best way possible? How can we use our skills in the right way to make an impact?

Inspired by Loom, our hope is we are able to make some difference in the current situation that is plaguing the world. Hopefully, many other businesses will carry this forward.

The Corona effects on the current supply chain

COVID-19 took us by surprise and we were not even close to being ready for a situation like this — Even Amazon’s models couldn’t have predicted this!

The global supply chain is fueled by outsourcing and thin margins, and COVID-19 has proven how fragile (or, rigid) it all is. Until now, the supply chains were stocking supplies efficiently in just the right amount (just-in-time manufacturing). However, when the demand spiked, everyone felt the effects of it.

“We do not see a supply shock in the sense of the availability,” said a UN economist to Bloomberg. “But there could be a supply shock in terms of logistics, not being able to move supplies from point A to point B.”

The majority of logistics players who influence the global supply chain (directly and indirectly) don’t have any visibility or a plan to deal with this kind of disruption. The supply chain just doesn’t have enough inventory buffer for a 20x shock!

Delivery is eating the world

In these times when all of us are locked down, delivery and logistics are what is powering the world.

Grocery companies such as Instacart, Walmart Grocery, and Shipt have seen their daily downloads surge by 218%, 160%, and 124%, respectively. Ecommerce Companies such as Amazon have hired 100,000 more workers to be able to respond to the surge in demand.

Deliveries of PPE (personal protective equipment) such as masks, ventilators have been surging almost 20x! Empty aisles and stock-outs in supermarkets are leading to logistics companies such as FedX and UPS partners working overtime.

Equipping our front line in this war:

If you are a logistics or delivery company, we will make our product available to you at heavily discounted rates!

The aim is to help you in monitoring & bridging the gaps and bottlenecks in your supply chain.

We have been also working on depicting the COVID-19 cases at much more granular levels on our current open source COVID tracking console to help companies estimate their demand and plan their network efficiently.

Are we throwing away a goldmine?

The incumbent supply chain process favors just-in-time and cheap manufacturing, which makes it difficult to sustain sudden shocks and supply shortages.

One of the prime reasons this happens is that this business is handled manually. The widespread use of location data is completely ignored across industries, which is why a large percentage of companies don’t even collect it in the first place. This has made both our preparation difficult as well as response reactive.

When companies have advance knowledge of where the disruption will come from and which products will be impacted, they have lead time to execute avoidance and mitigation strategies immediately — like shaping demand by offering discounts on substitutes, buying up inventory, booking capacity at alternate sites, controlling inventory allocations.

The supply chain becomes a company’s biggest risk during times of disruption. But by making it antifragile & resilient it can become its biggest strength & assure it combats future shocks.

How can we help delivery companies with location analytics?

In cases such as this when we can’t predict what’s going to happen in the next few hours, we need to react instead.

We are here to help delivery companies reach their customers in the fastest way possible and deal with this demand surge optimally.

And one of the ways in which we can react or plan more efficiently is to know the supply chain risks, and preemptively develop strategies. But how?

1. 24/7 Monitoring

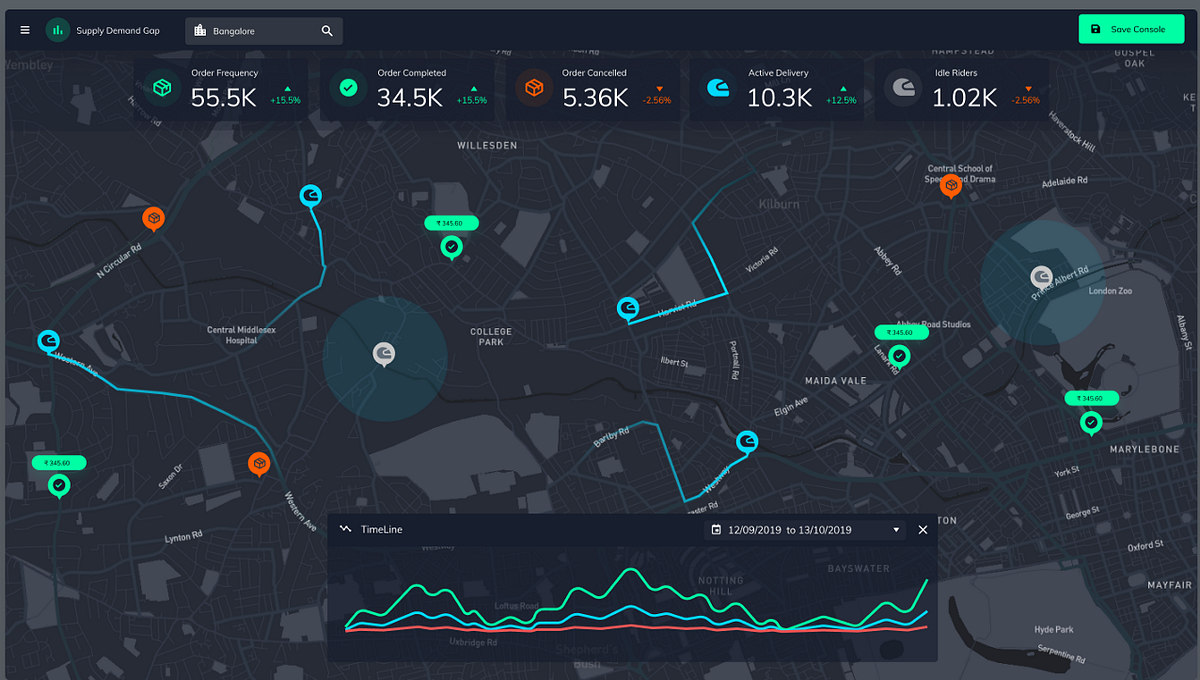

Locale helps in monitoring every KPI as well as the current movement of supplies and goods.

Being proactive about monitoring will help stay on top of disruptions, as you can triangulate within minutes or hours how their supply chain could be impacted in the days, weeks, months to come.

When businesses have no visibility over their supply chain beyond the first tier – especially over their tertiary suppliers – then they have no control and can’t locate where the threats to production capacity exist. This makes the situation to fight with the COVID-19 extremely difficult.

Monitoring is not only a strategy for dealing with the impacts of the COVID-19 outbreak, but also a best practice for supply chains at all times — David Shillingford, Resilience360. [Source]

2. Scheduling orders

With orders surging, promising the right SLA to the customer and then sticking to it becomes crucial. Locale will help you decide the optimum SLAs based on metrics such as the location, profitability, time taken as well as resources available.

For the orders which take the maximum time to get delivered, additional delivery charges might offset the cost incurred to deliver quickly. Locale can also help in reducing the TAT by pinpointing the pickups and drop-off points (or loading and unloading centers) that take a fair amount of time.

3. Managing inventory

Inventory management can be attributed to analyzing the following:

- Evaluating the inventory available: Accurately understanding the stock of inventory accessible (finished goods, spare parts, parts in transit, supply currently with customers and after-sales stock) to be able to keep the production on and being able to deliver to the end customers.

- Demand Mapping: Analyzing how the demand patterns of end-users for different categories of goods would be like and responding to the buying behavior of customers using metrics like order type, density, frequency. Another very important parameter to look at over here is the number of returns.

Running short on inventory is essentially a supply-demand mismatch problem that Locale can help you analyze and focus on the right locations. One of the companies that we are currently working with is a re-distributing inventory between their warehouses!

“Don’t wait until the gun is pointed at your head to think about mapping. Identify and estimate logistics capability, try to fastrack when possible & be flexible on the transport medium.” — Philip Palin, Researcher

4. Network mapping & planning

- Mapping: Tracing the entire supply chain, pinpointing the production units, nodes and routes is critical. This would help in identifying suppliers along with contractors and being aware of which parts originate and pass through which sites.

- Eliminating Inefficiencies: Locale can help in identifying routes that have the most deadhead and end miles historically or delays. Avoiding them, to the extent that it is possible can help in the long term!

- Warehouses: You can use Locale to track how your warehouses are performing depending on metrics such as shelf time of goods, demand within 2 km and intervene to either improve their performance or shut them down.

5. Expansion

The COVID-19 pandemic will also force companies to expand to previously unserviced areas. Using Locale, expand and provision your supply based on the latent demand rather than going on the ground team’s gut.

At Locale, we are working to update our COVID dashboard with much more granular data on cases to help you decide the right areas to target. We have also partnered with data providers to make external insights such as weather, mobility/traffic and satellite data available for you as plug and play that you can layer on top of your existing internal data.

According to Bloomberg, using correct data sets and forecasting tools will be crucial to companies as they navigate the current market environment and continue to make strategic decisions.

Let’s fight this, together!

At Locale, we are helping delivery companies to monitor their delays, deviations, take quick data-driven decisions & stay on top of their supply chains as we fight through these hard times.

We have built the right tools and infrastructure for companies to achieve these outcomes and give you an understanding of what’s going on in your map in the fastest way.

To get early access, get in touch with us at locale.ai or LinkedIn or Twitter.

This article is written by Aditi Sinha and it originally appeared on Medium.

For more business tips, check our entrepreneurship section and subscribe to our weekly newsletters.